Over the past couple of months I have received a few questions on how I set up the front and rear connection points for the anchor trolley on the 2012 Ride 135. Youtube and forums like KayakBassFishing.com are of excellent resources for learning about a basic anchor trolley setup. Instead of going through the whole process, consider this the Cliffs Notes version that focuses on the connection points - especially the rear one.

Since I don't use a rudder, I took advantage of the factory installed hardware to set up a functional trolley without having to drill additional holes into the kayak. Many of the Wilderness Systems kayaks have these bolts preinstalled from the factory. The key to this entire build is the use of 550 paracord because it flattens out making it ideal for the rear connection point.

These pictures were taken some time ago and I no longer use the zinc plated pulleys. I highly recommend Harken's H224 micro blocks. They can be purchased online at Austin Kayak HERE or locally at West Marine. They are well worth the investment and won't corrode.

Knot a loop of paracord and attach it directly to the pulley or use a snap as pictured. I like using the brass snaps so I can remove the rear portion of the trolley. This comes in handy in shallow spots where I can disconnect the rear of the trolley and use it as tow rope. This allows me to drag my kayak behind me as I move upstream and alleviates the need for separate tow line.

The install is simple. Use a phillips head screwdriver to back out one of the factory bolts found at various points on the rear of the kayak. Place the paracord loop around the bolt and retighten. The paracord will flatten considerably.

The woven portion on top of the paracord loop is just for looks. It is very easy to make a "King Cobra" weave with with a little practice.

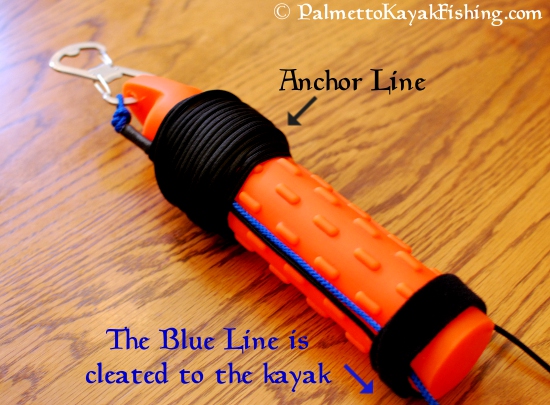

Check out the DIY anchor system instructions by clicking on the picture below.